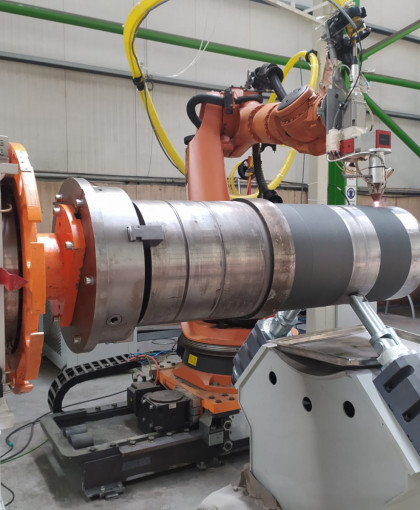

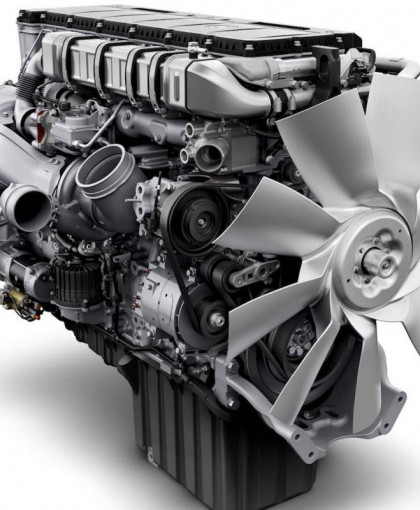

About Ipex Pump

Ipexpump, which sets out with the principles of 100% efficiency, quality and high performance, as a leading company in its sector since 2015, besides serving to thousands of companies in the country, it exports to 16 countries abroad.

It continues on its way with the strength and full points it receives from its customers and always provides the highest quality service.

In addition to air diaphragm & electric motor diaphragm pumps, in order to meet the needs of every sector in the machinery industry; produces and distributes gear pumps,...